ROLE OF IOT IN TEXTLE INDUSTRY

Internet has changed the landscape of industries in two decades. Internet has not only provided a platform for business, but also changed the business model as a whole. Currently, amidst the pandemic in 2020, we have witnessed the businesses turning more and more virtual. As a result, the concepts of IOT, AR, VR have already become some of the important tools in the current scenario. Now if we consider the current Textile Industry, we stand in the Industry 3.0, i.e. computer powered industry; one can consider it to be a bridge between the evolutions of a man driven industry into an artificial one. With the developments in Cloud Computing huge amount of data can be held and easily processed at a very short time. Tthis has helped in the application of IOT, AR, VR in the Industries and Textile Industry is no exception. Several Companies have already taken initiatives on that route. As a result the current Textile is in a swift transition from Industry 3.0 to Industry 4.0. So, the technology discussed here might not be very viable to the current market, however in the years to come this technology can be expected to be in mainstream

IOT has immense application in the Manufacturing sector, from the fibre to a finished fabric. By optimizing blends [3] to detection of fibre characteristics using AI and storing and processing data using IOT can help in reducing the variations in final product [4].

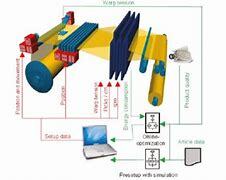

IOT integration in spinning and weaving machines can help in optimizing the process and reducing faults drastically. Monitoring of intermediate processes and automatically collecting data from Blow room to Ring Frame can help in enhancing the quality, reduce time, reduce man power, reduce paper work, and reduce machine stoppage time, enhances production and reduces cost. This monitoring of data from machine can give real time visibility of the process. It can also help in instant detection of machine faults, help in enhancing the machine life [5]. Rieter ESSENTIAL is an application by Rieter with such facilities is available in Play Store. Similar application in the weaving sector can be seen in Weaving Things, an industrial platform [6]. Automatic fault detection of textile products is another aspect of this IOT, Cognex, an American machine manufacturer produces machines and softwares in this aspect [7]. Even the efficiency, strengths and weaknesses of a worker, can also be assessed using this technology.

From Automatic colour matching (Datacolor for instance) , automatic sewing machines (YOHO in Japan for instance) , digital printing, to Floor space management IOT opens huge scope for the textile sector

ARTICLE BY

RATHINESHWARAN